Tube Production Roll Line Efficiency

Gregory Tube employs the top technology in the industry to efficiently produce quality galvanized steel tubing. One of the notable processes is roll line manufacturing. This method combines several processes to be integrated in the manufacturing line.

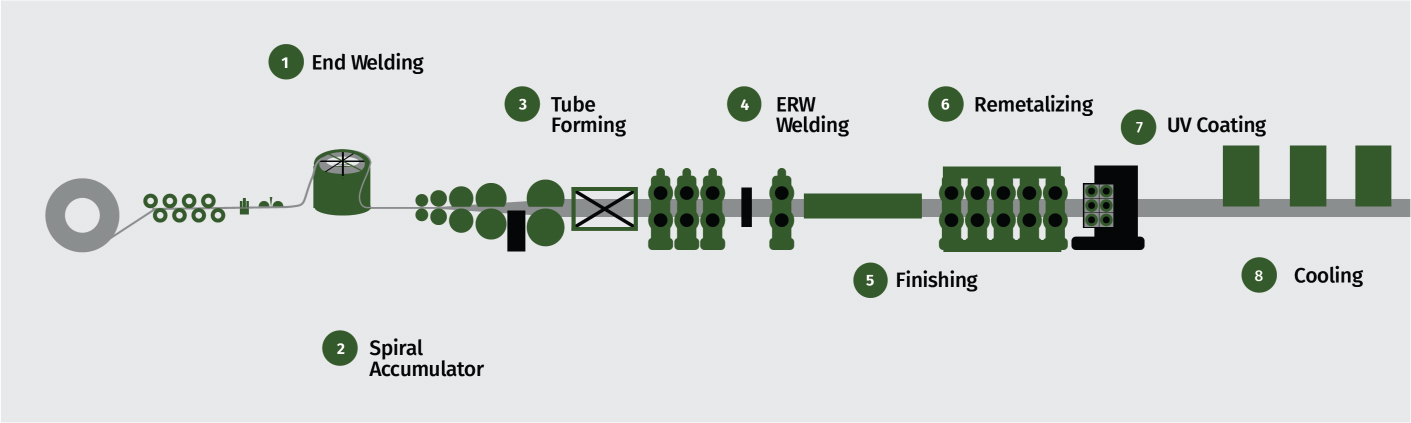

Roll Line Process

Roll line manufacturing is commonly referred to as an “in-line” repair process. With roll line manufacturing, our tube cleaning, internal coating, zinc application, thickness control, and cooling equipment are integrated into the production line situated between the forming and sizing mills. The process begins with end welding and moves on to the spiral accumulator. From there, the material goes to tube forming and ERW welding. The tubes are then sent to finishing and remetalizing before a UV coating application is applied prior to the finishing stage.

Advantages of Roll Line Production

Roll line production is an efficient manufacturing process. It allows for several steps to be completed while integrated into the production line. This process saves time and materials while producing a strong and quality product.

Contact Gregory Tube

Gregory Industries has been the authority for galvanized steel products for over 125 years. Trust us for dependable steel tube solutions for any building project. Contact us today for a quote on our tube products.