SMART Panels make installation quicker, safer, and easier

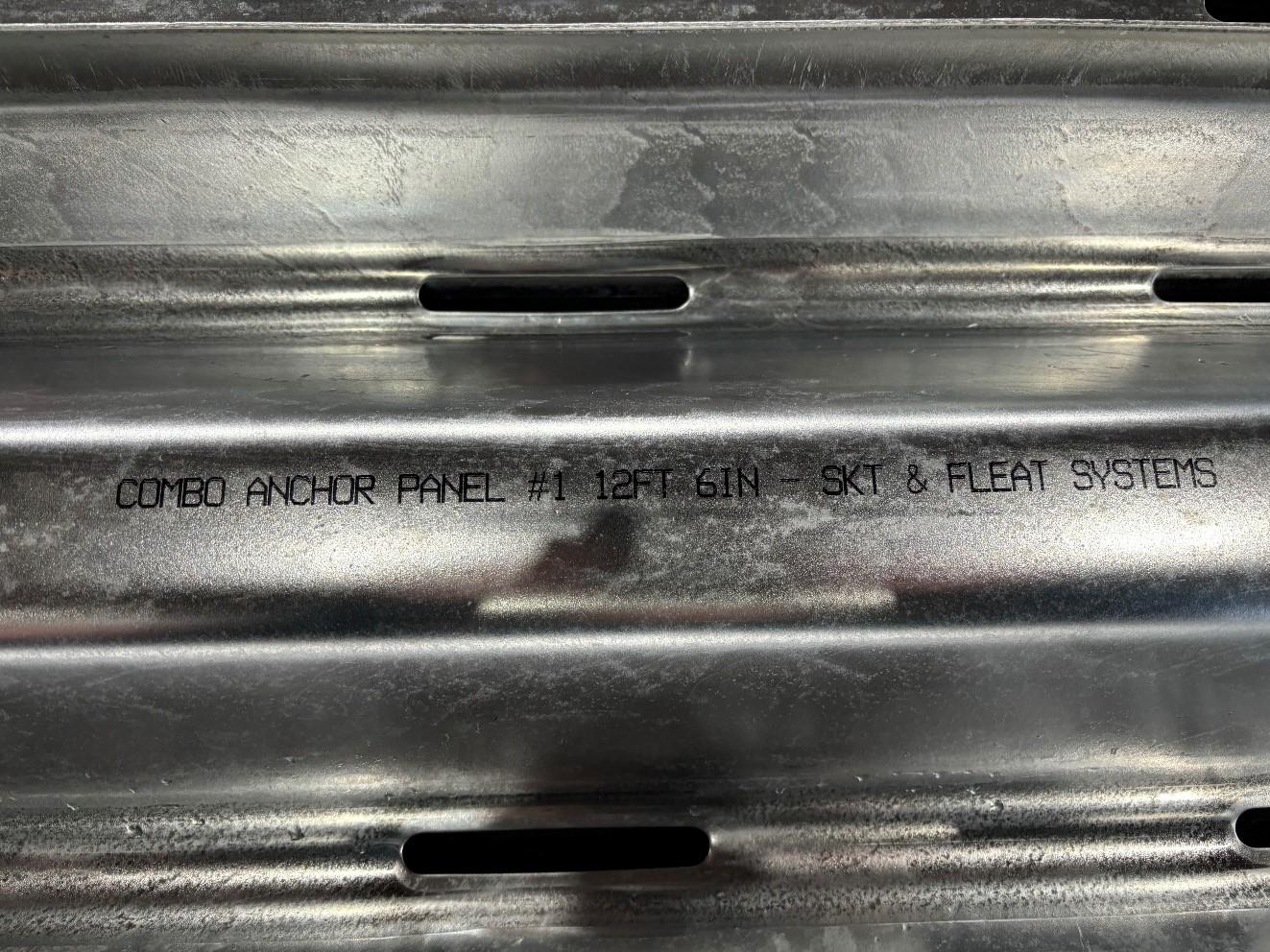

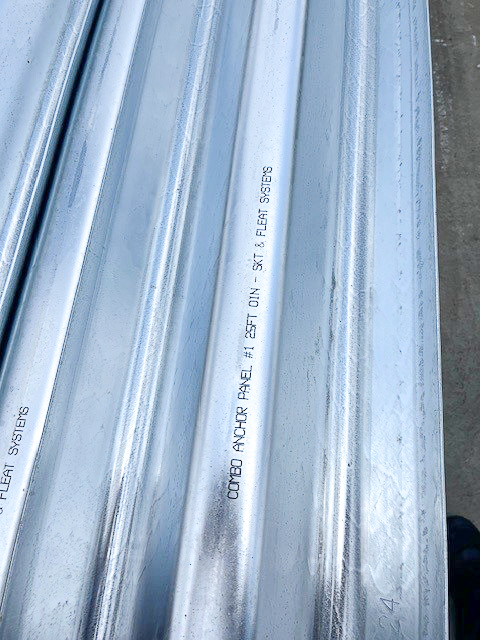

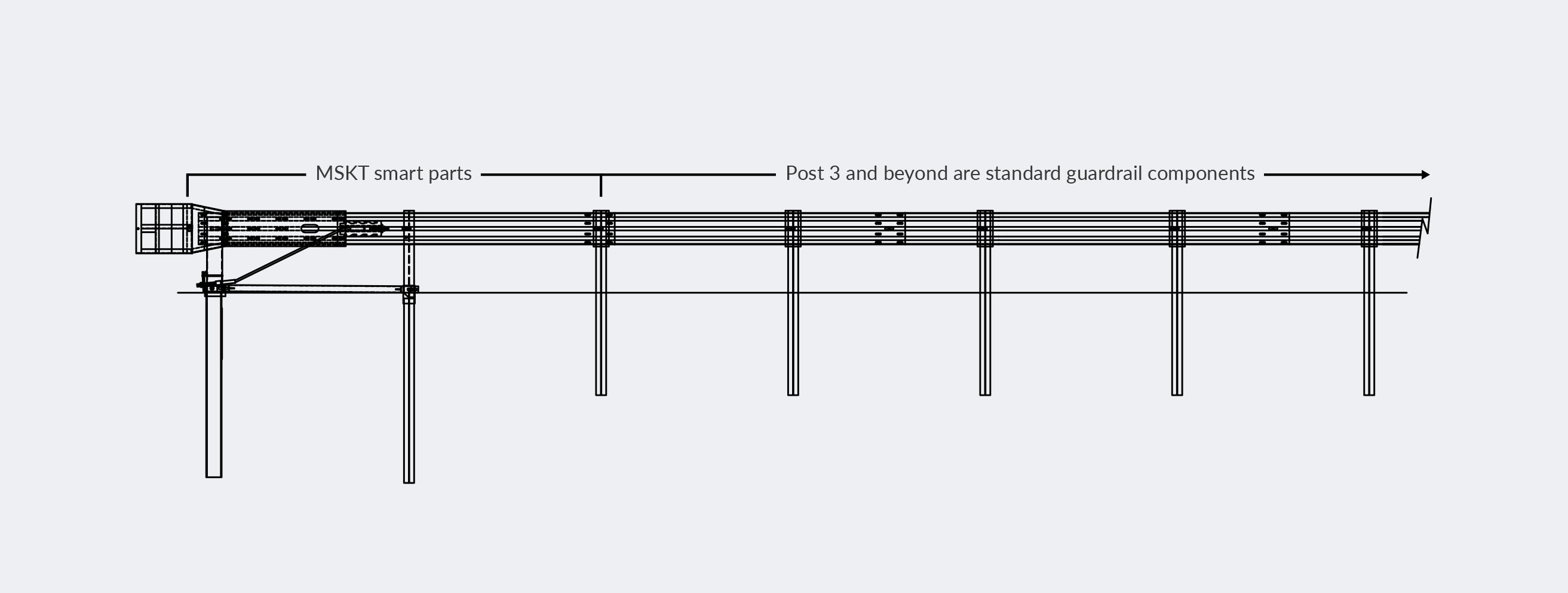

Gregory Highway, a leader in roadside safety solutions, has taken a significant step towards ensuring the accurate installation of End Terminals, including the MSKT, SKT, MFLEAT, FLEAT, and FLEAT-MT systems. In an effort to simplify and improve the installation process, the company has introduced inkjet printing on the unique W-Beam panel used in these terminal systems. This innovation provides clear and visible identifiers to aid contractors and installers in placing the correct guardrail panel into their proper functioning locations.

Why the Change?

End terminals play a crucial role in roadside safety by absorbing or redirecting the impact energy from vehicles during a crash. Accurate installation of these systems is essential to ensure that they function as designed in real-world collision scenarios. With multiple components in these systems, even experienced installers can face challenges distinguishing specific parts, leading to potential misplacement or installation errors. The new inkjet labeling process provides a straightforward solution to this problem. By labeling the unique W-Beam components with clear identifiers, Gregory Highway helps ensure that each part is installed correctly, reducing the chances of mistakes that could compromise the system's effectiveness.

Key Benefits of Inkjet-Printed Components

- Ease of Identification: Installers no longer need to rely solely on manual checks or reference guides to confirm that they are using the correct component. The printed identifiers make it clear where each panel should be placed, minimizing confusion

- Improved Safety: Proper installation of end terminals is directly linked to their ability to protect motorists during crashes. By streamlining the installation process, Gregory Highway helps ensure that these systems will perform to their full potential when needed

- Increased Efficiency: With clearly labeled panels, installers can work more efficiently, reducing the time needed to complete installations. This improvement not only speeds up projects but also reduces the risk of human error

The Systems Benefiting from the Change

The systems impacted by this improvement are some of the most trusted roadside safety solutions in use today:

- MSKT (MASH Sequential Kinking Terminal)

- SKT (Sequential Kinking Terminal)

- MFLEAT (Median FLEAT)

- FLEAT (Flared Energy Absorbing Terminal)

- FLEAT-MT (Flared Energy Absorbing Terminal – Median)

A Commitment to Road Safety

Gregory Highway’s introduction of inkjet printing on W-Beam components is part of a broader commitment to improving road safety by making installation processes more reliable and error-free. As roadside safety technologies evolve, this small but impactful innovation demonstrates the company’s dedication to supporting contractors, engineers, and road safety authorities in building safer roadways. At Gregory Highway, our highway safety products matter, because people’s lives matter.